socalkdl opened this issue on Apr 06, 2006 · 6 posts

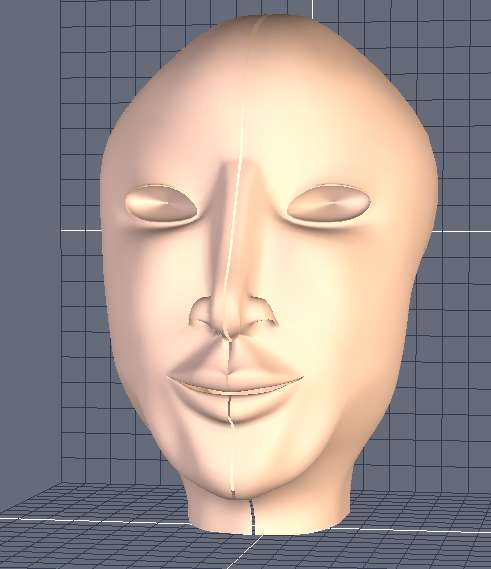

socalkdl posted Thu, 06 April 2006 at 9:42 PM

Patrick_210 posted Thu, 06 April 2006 at 10:26 PM

Looks like there is way to much separation for that tool. It only works at a fairly small distance I think. One way to fix it is to delete one side. Then select just the edges of the symmetry seam. Then set the size for that width to 0.00. It will be easy to know which dimension to set at zero because it will be the smallest one. After your seam has a zero size width, then create the symmetrical copy and weld the two halves together.

socalkdl posted Thu, 06 April 2006 at 10:53 PM

I've tried it with the seperation much closer, however I just now got it to work by fiddling until 90% of the points joined. I then used the weld tool to clean up the unwelded points. It is not the most intuitive tool but it does work. I should have joined the halves before I extruded the throat. I think my face had to much complexity along the seams.

socalkdl posted Thu, 06 April 2006 at 11:08 PM

Tonytrout on the Eovia forum for Hexagon just gave me an excellent way to make sure the points I want to weld are on top of each other. "You get the head nice and square facing you in orthographic view, select all the points on the join, and then in the object properties window set the SIZE to 0 (zero) on the axis perpendicular to the plane,(Hint: you have three (XY orZ) axis to choose from, the right axis to adjust to 0 is usually the one that has the smallest number in ) This lines up all the points, when you duplicate and weld the points are identical and weld. The beauty of this method is that you can accurately join the two halfs even after the centre line ponts have been messed around with. No matter how careful you are especially if you are using soft selections ,the centre line points always seem to get off centre."

Patrick_210 posted Thu, 06 April 2006 at 11:24 PM

That's basically what I said.

socalkdl posted Thu, 06 April 2006 at 11:44 PM